MIG Welding

As with the TIG process it does rely on still conditions so the inert gas can keep the oxygen in the air away from the hot metal, so any breezes must be avoided. It is a quick and reliable method of joining metals, and is used in most metal fabrications, railings, gates, vehicles, motorway bridges, buildings. Most general fabrication is done using a MIG welder.

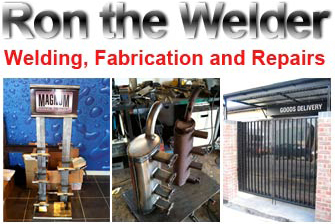

In the pictures below are examples of items I have fabricated or repaired using a MIG set

ARC Welding uses a consumable rod, but instead of a gas to shield the molten metal from the air it uses a coating on the rod, which melts as the same time as the metal does. This flux coating floats on top of the molten metal, keeping the oxygen in the air away and allows any impurities to float to the surface.

The metal and flux solidifies and the flux can be chipped away afterwards. There are many different types of ARC rod depending on the application. This welding method is ideal for mobile and site applications as it requires no gas and is more tolerant to windy and dirty conditions. For years this was the main method of electric arc welding. ARC welding offers good penetration and the ability to weld quite thick sections. Modern inverter sets are small and very portable, can run off of lower current and are tolerant to generators.

Cast iron and cast steel components are renowned for their brittle nature but can often be welded using a flux coated nickel rod, although cast iron is difficult to repair and can crack when cooling and is often cast from dubious materials.

Using these specialized welding rods and sometimes applying preheat; often a good repair can be made, saving time and money. Not all will weld successfully, but there are also other methods that can reclaim a broken casting, such as TIG brazing or silver soldering. I once repaired a cracked engine block using the old fashioned plumbers leading technique.

Also hardened cutting edged components can have their hard surface reinstated by using a ‘hard facing rod’. But if it’s broken, it is worth a go, if I don’t think it will weld I would say and if I can’t fix it, I’d only charge for the consumables used.

PREVIOUS WORKS INCLUDE

Fishing boat

Aluminium Catamaran

Horse Box modification

Aluminium chairs

Building Maintenance

Aluminium wheels

Diesel fuel tanks

Brewery fermenter alterations

Brewery customised equipment

Dog guards

Production welding

Labour only contracting

Crankcase repairs

Gearbox repairs

Cylinder head repairs

Cracked block repair

Security ground anchors

Outboard motor repairs

Trike fabrication and repair

Harley exhaust port rebuild

Plasma cutting

Galvanised steel

Wheel arch rebuild

Handrails Trailers

Juliet balconies

Display units

Custom roof racks

Motorhome ladders

Gates, railings and balustrades

Staircases

On site welding

Machine guards

Security grills

Plant

Machinery

Mowers

Farm Equipment

Digger Buckets

Container modifications

Security Door Lock boxes

Chassis repairs

Gas cutting

Wrought ironwork